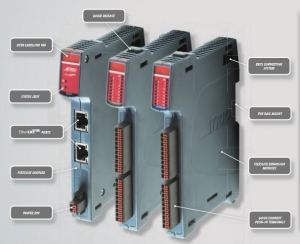

Trios Flexslice System

The EtherCAT Flexslice System is designed to let you do more! It offers fast flexible expansion for motion applications and can be used with Trio or 3rd Party Masters.

Trio’s Flexslice input/output modules provide a robust, high speed and flexible solution for both motion control and general automation. EtherCAT cycle times down to 250µsecs are supported and the bus coupler uses EBUS technology to bring all the sub-modules on to the EtherCAT network with no degradation in performance.

The Flexslice system makes available a selection of digital and analogue I/O terminals as well as motion modules with pulse + direction outputs designed for precise positioning of stepper and servo motors via suitable drive technology. The digital I/O modules have high-speed functionality. In addition, analogue modules and axis modules may be fitted to make a superbly tailored system that can be placed remotely from the master if needed.

All Flexslice modules support automatic addressing with the master to automatically detect and configure the modules on startup. The bus coupler supports up to 16 input/output modules which have a positive mechanical lock and bus connector, making a reliable EBUS connection through the backplane. The complete assembly can be DIN rail mounted.

FEATURES

• Use with Trio or 3rd Party EtherCAT Masters.

• High performance, flexible topology and simple configuration.

• Bus cycle time synchronised with Motion Coordinator Servo Period.

• Bus coupler module with 2 x RJ45 Ethernet ports for EtherCAT connection.

• EtherCAT protocol remains fully intact down to individual modules using the E-bus system.

• I/O functions tightly synchronised to motion using EtherCAT distributed clocks.

• Automatic mapping to the Motion Coordinator I/O system.

• DIN rail mounted.

• Multiple practical push-in connector options – No break outs required.

• Clip-together design with ‘quick release’ locks for mechanical integrity.

• User labelling facility.

• Machine builder custom functionality options.

Click here to download the PDF